Spray Distribution Systems

The following is a list of common components for spray onsite wastewater treatment systems

Common Components Involved

Septic Tanks

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater. These are normally concrete tanks in the ground which may or may not contain separated compartments. Septic tanks are often crucial part in a septic design. Septic system designs often site septic tanks based first on the local concrete manufacturer. Often times, the capacity of the septic tank sited is dependent on which manufacturer is used. Some manufacturers have longer wait times to manufacturer specific septic tank capacities.

Here is a collapsed septic tank. Visible is the multi-compartments and large volume.

Septic Tank Materials

Some septic tanks are made of alternate materials other than concrete, including polyethylene or fiberglass. Some benefits to utilizing these alternate materials is that they are lightweight and can be carried easier with a chain and a small excavator machine. Some septic tanks are so lightweight they can be lifted with several people.

A polyethylene plastic septic tank. Lightweight but often more expensive than concreted.

The water from septic tanks is sometimes called septic effluent. The term septic itself means without oxygen and septic effluent is composed mostly of bacteria and human feces. It is a highly contaminated liquid and human contact is dangerous. Septic tank effluent contains particles of sewage of size 1/16 to 3/16 inch in diameter. The waste strength is measure in Biological Oxygen Demand or BOD.

Septic tank effluent is high in solid wastes and pathogens. It must be further treated.

Septic Tank Function

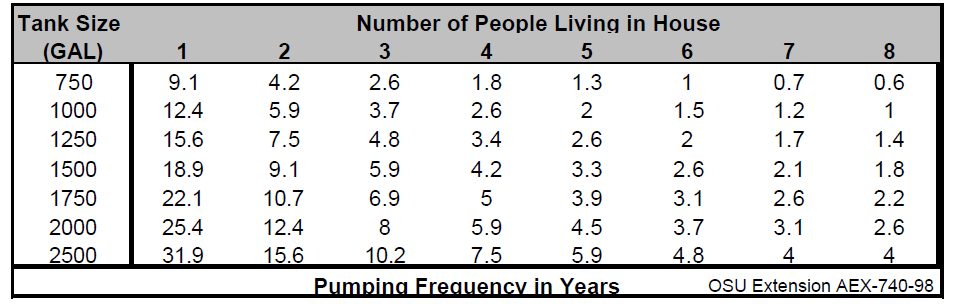

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater to further treatment. The solids can then be pumped at given intervals. The pumping frequency depends on the number of residents in the home and the capacity of the septic tank

Here is a septic tank pumping lookup charge based on residents and capacity.

Secondary Treatment

A treatment train is just a combination of technologies (active and passive) in a series that the water flows through. Secondary treatment is the use of aeration or filtration to further remove pollutants from the water as it moves through the treatment train.

Many advanced treatment systems are one tank with multiple chambers inside the tank. the secondary treatment compartment usually utilizes aeration, filtration, or a combination of both. the product of secondary treatment is usually a wastewater of significantly less polluted than primary wastewater.

How much of my yard will this take up?

I understand most concerns of homeowners is the impact this will have on their outdoor living space. The combination of tanks required to retain the solids and provide secondary treatment will be completely installed below ground. Unfortunately, it is required to provide access to the tank components through lids that extend at least 2 inches above the ground. The footprint of the tanks is generally 8 ft. wide x 20 ft. long and must be installed downslope of the house. The sewer main will be exiting the house below the final grade and fall at a general 1% slope towards the primary tanks.

Seen above are the typical green lids, generally 3 lids per treatment tank and one or two lids for the dosing tank. Also seen is a control panel which can alternatively be mounted on the house at a greater cost.

Above you can see the tanks without soil and grass cover. These tanks require electricity to power the aeration motors and control panels.

There are a two main different methods of secondary treatment and many, many proprietary products market and also non-proprietary approved proven construction methods for secondary treatment:

Maintenance required for secondary treatment units are typically recommended at 6 month by the manufacturer. The maintenance includes ensuring any aeration motor is functioning properly and free from obstruction and any filtration is cleaned.

Tertiary Treatment

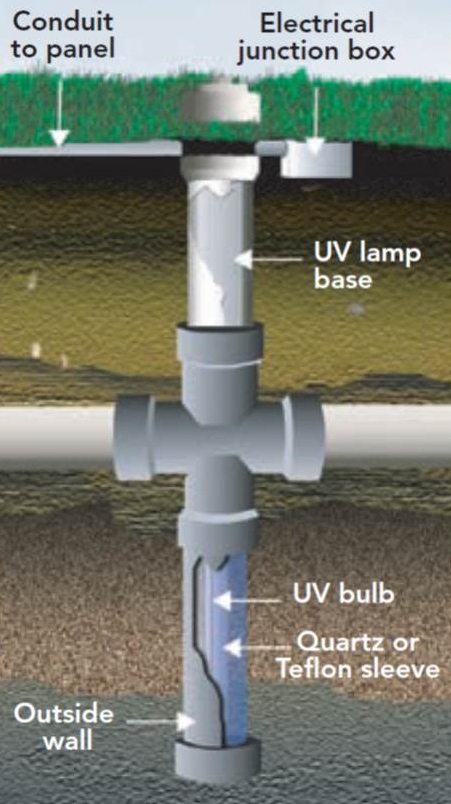

The final component in the treatment train is a disinfection technology. There really are only two types available on the market for residential onsite wastewater treatment: Ultra-Violet (UV) Light and Chlorination.

By far, the most popular form of disinfection of residential wastewater is UV Light.

Disinfection is part of the entire wastewater treatment package. Disinfection of wastewater really can only occur when the wastewater has mostly been treated. This means the water has been significantly filtered and most of the large solid waste has been removed. Therefore, the effectiveness of any disinfection process depends largely on the different characteristics of the wastewater, the intensity of the disinfection, and the amount of time the water is exposed to the disinfection process.

The most effective wavelength of light to inactivate bacteria or viruses is the range of 250-270 nanometers. This is a form of energy radiation which damages the bacteria or virus DNA, or the information of how to copy the organism. The great thing about UV disinfection of residential wastewater is that there is no residual pollutants as is the case of chemical disinfection methods.

UV Light bulbs have a life expectancy of 1-2 years typically and can cost around $40-50 (Year 2023).

Spray Heads

Spray heads for wastewater for residential onsite wastewater treatment typically involves some very inexpensive recycled wastewater irrigation spray head. The spray heads are typically housed inside of a pvc pipe conduit and can contain electrical input for heat tape in colder climates, air release valves, pressure gauges, and shut off valves.

The spray heads are typically manufactured in 5-6 ft. sections of conduit and sit 2-3 ft. below the ground, in climates which receive snow cover. In warmer climates, spray heads can be installed at the ground or slightly above grade.

Here is a spray head, which sits approximately 3 ft. above the ground.

What happens in freezing conditions?

Spray heads have gone through many iterations of design in cold climates. It has been found that by wrapping a heat tape around the spray head inside the conduit, which activates in freezing temperatures, the spray heads are prevented from freezing.

This picture shows a cut-away of the rotor based spray head showing an applied heat tape.

There are many different spray heads on the market include rotor based, ratchet activated, and dual nozzle and single nozzle.

Here is a custom dual nozzle spray head from Wastewater Solutions (Ohio). The benefit of dual nozzles is an increased output of water and less dose time.

What are the benefits of spray systems?

Many installation contractors will install spray systems at a significant lower cost than other labor intensive onsite wastewater treatment systems such as mound, leaching trenches, drip, and low pressure pipe systems. Most contractors can have the system installed in a day or two and they can be installed in wet or snowy conditions.

Other systems such as mounds, etc. have to be installed during dry weather making scheduling of work limited. Spray systems allow contractors to work in the winter and rainy season.

Another reason is that where other systems require clearing of areas of trees from a lot, Spray heads can be installed in the woods, and actually help water the trees.

Here you can barely see the black spray heads from the driveway of this house.

How much of my yard will the spray area take up?

Typically, the spray radius is 30-40 ft. and requires a 360 degree application with at least 2 nozzles. This will require approximately 4,000 sq. ft. of property and there may be set-back requirements from the edge of the spray to the property line. For example in Ohio, the spray edge much be a minimum of 50 ft. from a property line, so for a 40 ft. spray radius, the spray head must be 90 ft. from the parcel line.

Above you can see the view from a patio of 2 spray heads on a wooded hillslope. Barely visible and the odorless water is watering the trees.

Here is the same property showing the spray in action looking down the hill. Notice the pine trees which will eventually grow to a height to totally block all view of the spray.

Won't my pipes freeze in the winter?

Most spray systems are installed to drain back to the dosing tank after each pumping by a weep hole installed in the pump line in the dose tank.

Looking into the dose tank lid, you can view the water draining back from the dose event that just happened.

What if I'm walking around my yard and I get soaked?

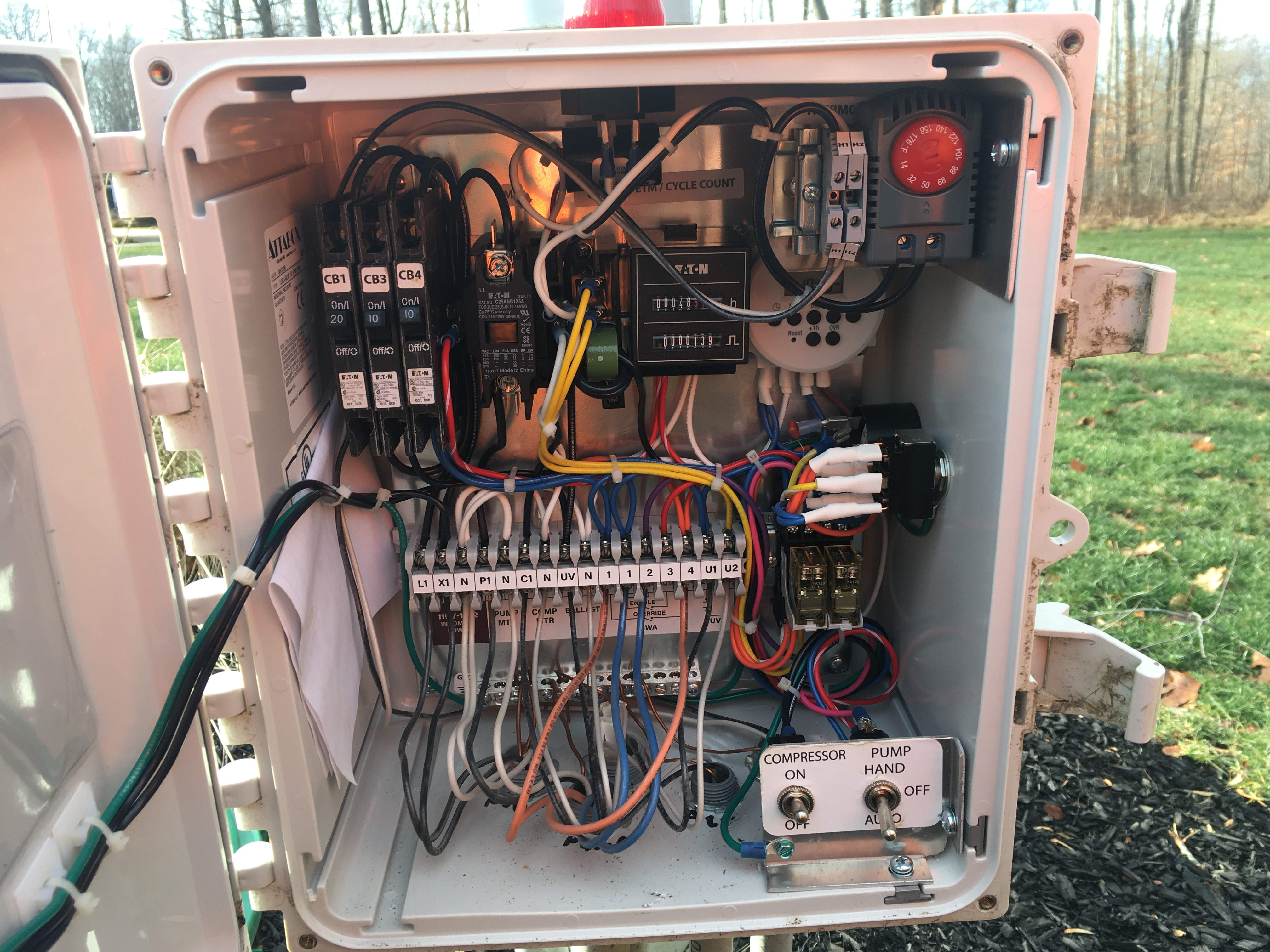

Most spray systems are required to be installed with a time-dosed control panel. Typically, spray is set to turn on around 5 am. This is at an early enough hour but not too early prior to the sun rise to prevent mildew growth on grass or trees before the sun can do its work through evaporation.

Here is an inside view of a control panel. This model includes a timer, cycle counter, temperature sensor for the heat tape, and a manual control.