Leaching Trench Fields

The following is a list of common components for leaching trench field treatment systems

Common Components Involved

Septic Tanks

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater. These are normally concrete tanks in the ground which may or may not contain separated compartments. Septic tanks are often crucial part in a septic design. Septic system designs often site septic tanks based first on the local concrete manufacturer. Often times, the capacity of the septic tank sited is dependent on which manufacturer is used. Some manufacturers have longer wait times to manufacturer specific septic tank capacities.

Here is a collapsed septic tank. Visible is the multi-compartments and large volume.

Septic Tank Materials

Some septic tanks are made of alternate materials other than concrete, including polyethylene or fiberglass. Some benefits to utilizing these alternate materials is that they are lightweight and can be carried easier with a chain and a small excavator machine. Some septic tanks are so lightweight they can be lifted with several people.

A polyethylene plastic septic tank. Lightweight but often more expensive than concreted.

The water from septic tanks is sometimes called septic effluent. The term septic itself means without oxygen and septic effluent is composed mostly of bacteria and human feces. It is a highly contaminated liquid and human contact is dangerous. Septic tank effluent contains particles of sewage of size 1/16 to 3/16 inch in diameter. The waste strength is measure in Biological Oxygen Demand or BOD.

Septic tank effluent is high in solid wastes and pathogens. It must be further treated.

Septic Tank Function

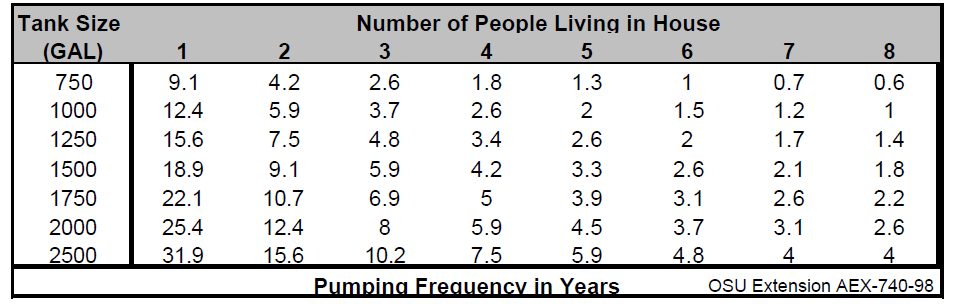

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater to further treatment. The solids can then be pumped at given intervals. The pumping frequency depends on the number of residents in the home and the capacity of the septic tank

Here is a septic tank pumping lookup charge based on residents and capacity.

Secondary Treatment

A treatment train is just a combination of technologies (active and passive) in a series that the water flows through. Secondary treatment is the use of aeration or filtration to further remove pollutants from the water as it moves through the treatment train.

Many advanced treatment systems are one tank with multiple chambers inside the tank. the secondary treatment compartment usually utilizes aeration, filtration, or a combination of both. the product of secondary treatment is usually a wastewater of significantly less polluted than primary wastewater.

How much of my yard will this take up?

I understand most concerns of homeowners is the impact this will have on their outdoor living space. The combination of tanks required to retain the solids and provide secondary treatment will be completely installed below ground. Unfortunately, it is required to provide access to the tank components through lids that extend at least 2 inches above the ground. The footprint of the tanks is generally 8 ft. wide x 20 ft. long and must be installed downslope of the house. The sewer main will be exiting the house below the final grade and fall at a general 1% slope towards the primary tanks.

Seen above are the typical green lids, generally 3 lids per treatment tank and one or two lids for the dosing tank. Also seen is a control panel which can alternatively be mounted on the house at a greater cost.

Above you can see the tanks without soil and grass cover. These tanks require electricity to power the aeration motors and control panels.

There are a two main different methods of secondary treatment and many, many proprietary products market and also non-proprietary approved proven construction methods for secondary treatment:

Maintenance required for secondary treatment units are typically recommended at 6 month by the manufacturer. The maintenance includes ensuring any aeration motor is functioning properly and free from obstruction and any filtration is cleaned.

Some believe that leaching trench life span can be increased by adding secondary treatment due to reducing suspended solids in the wastewater going to the leaching trenches.

Leaching Trenches

Regardless of what you call these systems locally, they all are essentially constructed the same. The water from septic or treatment tank is delivered to the soil via trenches. The water is delivered via gravity or pumped (either timed-dosed with a control panel or demand dosed). There typically is a distribution box or feeder box which works to deliver the wastewater to either all trenches at once (parallel) or one trench at a time (sequential)

This configuration shows a Sequential distribution method with gravel as the aggregate media. One trench fills up then the water moves to the next trench.

Here is a Parallel distribution method configuration which all trenches are dosed at the same time. The distribution media used is a Gravelless chamber product.

How long do leaching trenches last?

The most fundamental part of the planning process is a good soil test by a professional evaluator. This is generally done by a profile analysis of the different layers of soil at each depth. A profile analysis looks at the clay content, type, shape, and grade of soil. It also identifies the depth of limiting conditions in the soil. These are depths at which the type of soil/geology there prevents downward flow of water.

If soil is sandy and gravelly then you may never be able to use enough water to notice any surfacing or flooding of the trench field. A clay soil could cause a leaching trenches to fail or completely flood shortly after being installed. Proper planning is essential and hiring a qualified designer and soil evaluator is very important.

Here are some sandy soils which can absorb a lot of water due to large space between particles.

Clay soil packs together tightly and this platy structure prevents downward flow of water.

Here is a Sequential distribution box totally saturated from a rain event the day before. This was a poorly planned leaching trench field, with poor soils and in a flat area, promoting poor downward and horizontal movement of the water in the soil.

A properly planned leaching trench field can last greater than 20 years. Other factors that can extend the life span, include installing a secondary treatment unit, installing a timed-dosing control panel, and installing low flow water fixtures in the home. The water used in the home, must be dispersed into the soil and the less water, the longer your system life-span.

Timed-dosing control panels prevent large volumes of water used in the home from going out the leaching trenches all at once and prevents flooding.